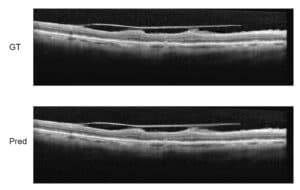

A robust procedure for lens markings detection and localization was therefore requested by one of our clients. RSIP Vision has developed such robust procedure, based on pattern recognition of lens markings in poor contrasted images. The poor contrast is a direct result of the glossy medium of the lenses in non-modern hardware for lens inspection. The algorithm developed by RSIP Vision is an image processing based solution which overcomes these difficulties using a sequence of tailor-made algorithms.

RSIP Vision’s algorithm initially detects the center of the lens and subsequently the direction of cylinders. By means of custom pattern recognition algorithms, a broad range of lighting condition can be handled in a robust manner. Faint or broken lines on lenses, appearing as a cause of partial contrast, are dealt with as well. A software solution is offered by RSIP Vision which facilitates lens design. Out models can be adapted to various glass frames, positioning of drilling points, and non-conventional, fashionable lens design.

By a robust lens markings detection, RSIP Vision’s algorithm facilitates the design and manufacture of lenses by overcoming difficulties of lightning and contrast conditions. A fully robust solution for lens markings detection contributes not only to the direct improvement of glass quality, but also to reduction of human errors. Lens markings detection can serve as a fault detection system during lens shaping, whether by a human operator or by an automated diamond-head cutter.

RSIP Vision has a proven track record in building custom-made solutions for optics and for ophthalmology. With several decades of operation around the world, RSIP Vision has gathered both the knowledge and experience to provide computer vision, image processing and machine learning solutions, meeting stringent industrial standards of precise measurement. Please consult RSIP Vision’s project page to learn more about our operations and expertise.