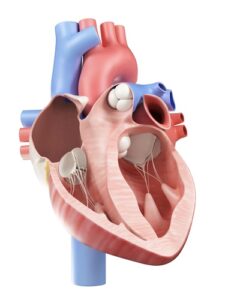

Left Ventricle Statistical Shape Modelling

Statistical shape modelling is a powerful tool for visualizing geometric and functional patterns of variation in all organs and also a reliable left ventricle shape model can prove itself very useful, though quite challenging to construct. RSIP Vision knows how to do this and many other image processing solutions for cardiology. And since cardiovascular diseases account for million of deaths per year in the developed world, this work is of vital importance.

Read More

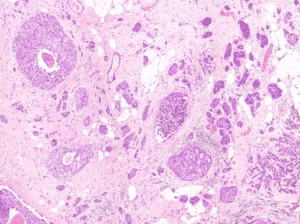

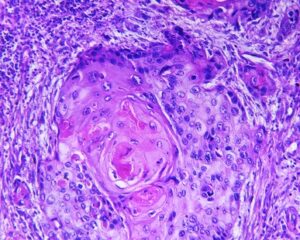

Fabric Inspection with Texture Analysis

Vision-based production inspection systems using camera-based scanning are now quite common in in-line production lines such as in steel, leather and fabrics manufacturing. Inspection is a crucial process since it can reduce process and enhance product quality. We recommend here a texture analysis for defect and novelty detection in fabrics and non-structured surfaces. Our fabric inspection algorithms are developed to detect deviations from local pattern and texture, anomalies and defects.

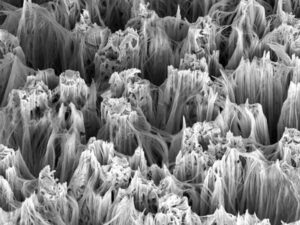

3D inspection and crack detection

Industrial production is prone to surface defects and it often needs to be inspected prior to shipment, when still in a semi-finished status. Cracks being very frequent in many types of material, vision-based crack inspection and detection is cost effective and offers high reproducibility and reliability. Here is a contact-free procedure using laser scanning, which can be placed in-line for continuous inspection during production.

Read More

Road signs detection with machine learning

Frequent variations of speed limits (mainly due to roadwork and other maintenance), offer ADAS technology a chance to help drivers respect traffic laws and security. The traffic signs detection software developed by RSIP Vision detects a road sign at distance and verifies via machine learning if it is a speed limit sign and what that limit is. These detection and classification processes being based on machine learning, our application is able to do things that regular “engineered” software cannot do.

Read More

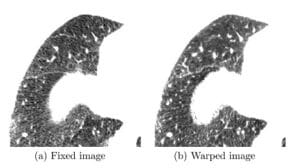

Flat Panel Display Inspection

This project compares the performance of a new inspection procedure of Flat Panel Displays (FPD) with the results obtained using a previously existing process. The goal was to demonstrate the correct detection and defect position reported by the new technology. This was done by putting in place a system in charge of image acquisition software and control which drives the captured frames to a sophisticated algorithmical registration analysis system developed by RSIP Vision.

Read More

Wafer defect detection by feature matching

Detection of microscopic defect in wafers and printed circuit boards is a standard procedure in the manufacturing process. The time consuming human inspection has been replaced in nearly all production lines with an automatic in-line camera-based examination, which can be very effective usingcomputer vision and image processing technologies to detect any anomalies. Via algorithms of feature extraction and matching, RSIP Vision is able to track defects leading to dramatically improvements in reliability and usability.

Read More

Barcode Detection in complex environments

Automatically localizing and reading barcodes captured by a smartphone-based cameras have great value for industrial and personal applications but create new technical challenges: quality of the image, motion blurs, unpredictable distance to barcode, non-uniform orientation and unknown location of the barcode itself. Image processing and computer vision algorithms can solve these issues: ask RSIP Vision how we do it.

Read More

Real time OCR in natural scenes

With the advancement in technology, the demand for OCR in natural environment is growing, even though outdoor conditions are far from being optimal for machine vision applications: occlusion of written text, text orientation, font style, blurring due to camera motion, and lighting conditions can prove themselves significant challenges in the task of performing real time OCR. Great progress has recently been made in the recognition of characters partially occluded and under heavy noise. RSIP Vision tells you how.

Read More

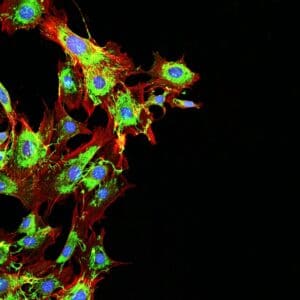

Live cells tracking

Manual cell inspection is limited to tracking a relatively small number of cells in short periods of time and it is prone to human errors. On the other hand, computer vision algorithms can be used to perform fast scanning, segmentation and tracking of large cell populations over long periods of time. Taking advantage of our experience in segmentation, microscopy and machine learning, this procedure helps saving both labor and time, hence enabling more timely diagnostic and therapy.

Read More

Computer vision in Israel

The spectacular growth of digital imaging technology has made the solution to the problems of automated image interpretation much easier; the results are quite exciting