![]()

Although improvement in the manufacturing techniques aims at eliminating these defects during production, some defects still remain and can only be visible after wafer manufacturing. A manual scan of a production batch is immensely time consuming and therefore various sensor aided automatic scanning methods have been developed to detect imprint faults and pinpoint defective wafers.

Automatic visual inspection of semiconductors

Automatic detection of wafers and elimination of defective parts in the semiconductor industry is now a part of the routine manufacturing pipeline. The economic implications are obvious: high quality yield is sold in higher price, data reliability increases, faultless parts increase manufacturer’s reputation, and so forth.

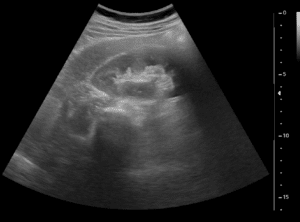

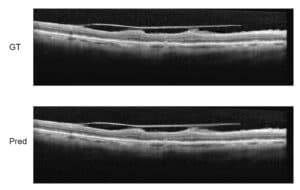

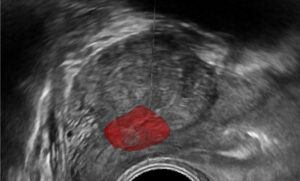

Visual inspection of semiconductors is performed using camera mounted on a microscope. The sample wafers are examined by computer vision algorithm and rapidly scanned: the algorithm is designed to quickly detect and classifies defects. In this process, the algorithm can ensure that the right information (template) was reliably imprinted on the silicon wafer.

RSIP Vision has been involved in the construction of reliable chip scanning algorithms to detect and classify faults post manufacture. RSIP Vision developed an advanced software and vision system which conducts image registration and model comparison (among other processes) in its thorough inspection of each reticule, enabling a very fast and accurate visual inspection of semiconductors.

Our detection software saves our client money and effort through the capture of critical errors early on in the semiconductor production process. At RSIP Vision we’ve been working in the visual inspection field for decades. Please contact us to discuss how we can work together to meet your semiconductor optical inspection requirements.